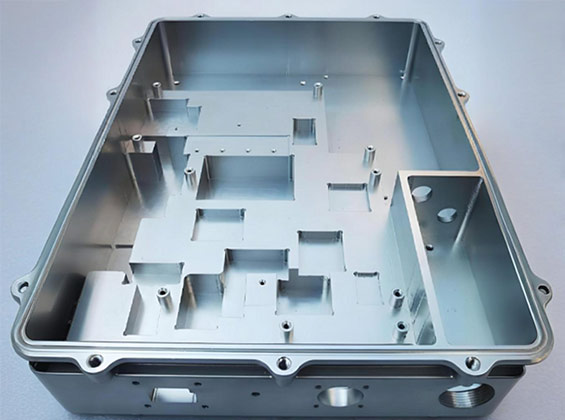

CNC Cavity Heat Sink

1. First, distinguish between tool materials: those with good toughness and low hardness are suitable for rough machining, while those with poor toughness and high hardness are better for finishing. During machining, take care not to contact the fins of the aluminium profile heat sink to avoid damaging them.

2. When CNC machining radiators with excessive height, employ layered roughing with cutters of varying lengths. Following roughing, utilise smaller cutters to remove residual material.

3. Employ flat-bottomed cutters for machining flat surfaces, minimising the use of ball-nose cutters to reduce processing time. For machining integer-degree slopes, utilise tapered cutters.

4. For high-hardness aluminium profile radiator materials, select climb milling; for low-hardness materials, select conventional milling.

These are the key considerations for CNC radiator machining. We hope this information proves helpful.