Challenges and Solutions for Heat Dissipation Issues in LED Lights.

Challenges and Solutions for Heat Dissipation Issues in LED Lights.

-Why Heat Dissipation is Critical in LED Luminaires?

Research data indicates that when LED chip junction temperature rises from 25°C to 60°C, luminous flux drops to 90%; at 100°C, it significantly decreases to 80%; and at 140°C, only 70% of luminous flux remains. This phenomenon underscores the critical role of heat dissipation in maintaining LED luminous efficiency. If heat dissipation in high-power LED luminaires is inadequately addressed, operating temperatures will inevitably increase, leading to elevated junction temperatures. This chain reaction causes chromaticity point shift, reduced color rendering index (CRI), increased correlated color temperature (CCT), and ultimately results in significant luminous efficacy degradation and shortened lifespan. Risk of overheating will cause permanent damage.

For every 2°C increase in component, reliability decreases by 10%. Particularly in white light lighting systems where multiple LEDs are densely arranged, heat dissipation challenges become more pronounced. Therefore, effective thermal management has become a critical aspect of high-brightness LED applications.

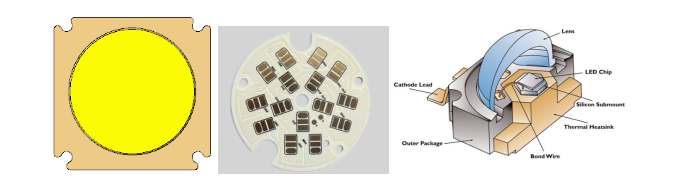

-How the heat transferred from LED light?

Similar to traditional light sources, LED lights generate heat while operating. The amount of this heat is closely related to the overall luminous efficiency of the LED. Research shows that only about 30-40% of the input electrical energy can be converted into light energy, while most of the rest is converted into heat and released in a non- Radiation manner. And as the temperature increases, the efficiency of light energy conversion will decrease further. For example, the maximum heat dissipation of a 600W power input light can reach 420~480W.

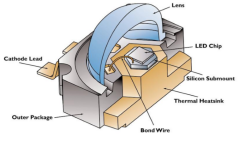

How Led working (Principle of heat transfer)

LED heat dissipation can be explained from three perspectives: heat conduction, convection, and radiation. Heat conduction refers to the transfer of heat through direct contact between the LED and a heat sink with a higher thermal conductivity. The thermal resistance between the LED and the heat sink is important, as a lower thermal resistance can improve the heat transfer efficiency. Thermal interface materials with high thermal conductivity can be used to reduce the thermal resistance. Heat convection refers to the transfer of heat through the movement of a fluid, such as air or liquid, over the surface of the LED and heat sink. By increasing the surface area of the heat sink and promoting air flow or liquid circulation, the heat can be dissipated more efficiently through convection. Heat radiation refers to the transfer of heat through electromagnetic waves, such as infrared radiation. By using materials with high emissivity, the heat can be dissipated through radiation. Combining these three methods can improve the heat dissipation performance of LED and ensure its long-term stability and reliability.

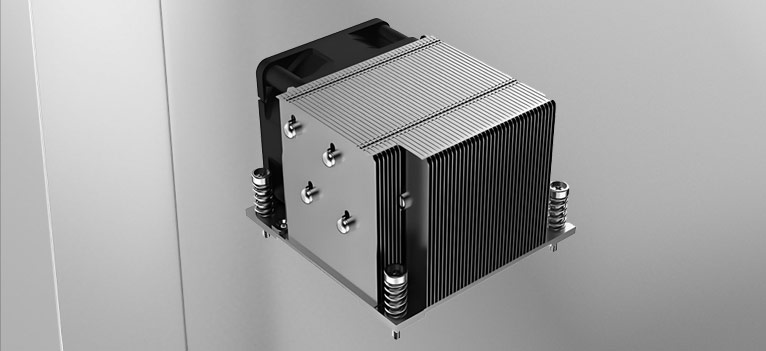

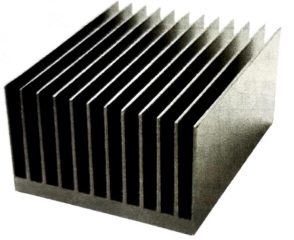

How to use Heat sink to dissipate heat for LED?

to dissipate heat for LED, generally there are three main methods: using heat sinks, applying thermal interface materials, and using heat pipes. Heat sinks are the most commonly used method, which can increase the surface area for heat dissipation and reduce the temperature of the LED. Thermal interface materials can improve the heat transfer efficiency between the LED and the heat sink, thus enhancing the heat dissipation effect. Heat pipes can transfer heat away from the LED quickly by evaporating and condensing a working fluid inside the pipe. Other methods, such as using liquid cooling or air cooling, are also being developed to improve the heat dissipation performance of LED.

How to improve LED heatsink performance.

Here is the LED lighting solutions from Yumin Cooling. Yumin can Provide professional cooling solutions and manufacture High performance Heat sink for high power led light.

1. LED Heatsink Material

Currently in the market, heat sinks are mainly made of aluminum alloy or copper. Aluminum alloy is favored for its affordable price and light weight, but its thermal conductivity is slightly inferior to copper. Copper has excellent thermal conductivity, but it is more expensive, difficult to process, and relatively heavy. In addition, copper heat sinks have problems such as small heat capacity and easy oxidation. Copper-aluminum composite materials are commonly used in the market, balancing thermal conductivity and cost. By considering the advantages and disadvantages of copper and aluminum, modern heat sinks are often made using copper-aluminum composite manufacturing processes, aiming to balance performance and cost.

2. interface materials- Using correct Thermal interface materials.

Thermal interface materials are used to improve the heat transfer efficiency between the heat-generating component and the heat sink. They fill the gaps and irregularities between the surfaces of the component and the heat sink, reducing the thermal resistance and enhancing the heat dissipation performance. Materials with high thermal conductivity, such as metals, ceramics, and some polymers, are commonly used as thermal interface materials. Ensure the chip and the heat sink can be in full contact.

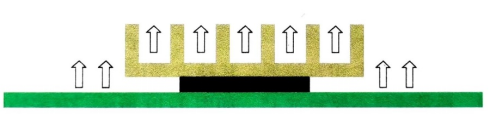

3. Convection- The heat sink transfers heat into the surrounding air.

Convection can improve the heat dissipation performance of LED by increasing the surface area of the heat sink and promoting air flow circulation. By moving the heat away from the LED through the movement of air, the heat can be dissipated more efficiently. The convection performance can be further enhanced by using heat pipes or even liquid cooling systems, which can transfer the heat away from the LED quickly and effectively.

There are two main ways in which a heat sink removes heat: nature Convection and Force Convection. The effectiveness of nature Convection is limited and it is difficult to effectively deal with situations of high heat dissipation. In contrast, Force Convection takes the heat away from the fins actively through devices such as fans, which is more efficient and compact. For example, active cooling accelerates heat dissipation through devices such as fans, so it is more widely used in practical applications.

4. Radiation-A small part of heat is released as infrared energy

Heat radiation can be used to improve the heat dissipation performance of LED by using materials with high emissivity. Emissivity refers to the ability of a material to emit thermal radiation, such as infrared radiation. By using materials with high emissivity, the heat can be dissipated through radiation. Materials with high emissivity include metals, ceramics, and some polymers. In addition, the surface finish and texture of the material can also affect the emissivity and thus the radiation performance of LED.

LED heat sink types (LED heat sink manufacturing methods)

1. LED extruded aluminum heat sink

LED extruded aluminum heat sink is formed by aluminum extrusion, and by CNC machining, embedded in heat pipe, and finally finished by surface treatment. the aluminum alloy is melted and cast into a billet. Then, the billet is heated and extruded through a die to form a long profile with a specific shape and size. The extruded profile is then cut into desired lengths and machined to create fins or other features for heat dissipation. After that, the aluminum heat sink is subjected to surface treatment, such as anodizing or painting, to improve its heat dissipation performance and corrosion resistance.

Good heat Dissipation Features:

- relatively low mold cost.

- customized in various shapes and size.

-Higher machining efficiency

-forming is relatively simple.

- Fin can be done very thin, high thermal conductively.

2. LED die casting heat sink

Die casting heat sinks are popular for their high precision, good heat dissipation performance, and low cost for high volume production. However, they may have higher thermal resistance compared to other manufacturing processes due to the presence of porosity and oxide layers. Typically, we manufacture it using ADC10 and ADC12 as die casting materials. Meanwhile the casting heat sinks cannot be made very thin, so it is difficult to maximize the heat dissipation area,

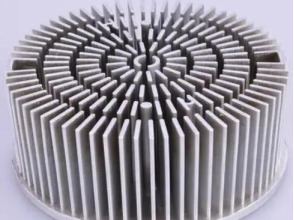

3. Led Cold forged heat sink

Cold forging is a manufacturing process for heat sinks that involves compressing a metal billet at room temperature to create a part with a specific shape and size, The advantages include high thermal conductivity, high precision, and low cost for high volume production. Cold forged heat sinks can also have a smooth surface finish and good dimensional stability. Typically, we manufacture it using AL5052, AL6061, AL6063 as Cold forging materials. It is a low cost solution. This process is mainly used in the manufacture of LED light heat sink.

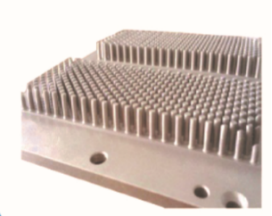

4. LED stacked heat sink

LED Stacked heat sink is a type of heat sink that is made by stacking multiple layers of metal, typically aluminum or copper, on top of each other. The layers are usually bonded together using thermal interface material (solder) to ensure good thermal contact between them. Usually, Use copper base and aluminum stacked fin to manufacture through welding. Heat pipes have higher Thermal conductivity. Can transfer heat from LED to Stacked fin quickly, and the heat on the heat sink is then quickly carried away by air convection.

In general, with the demand for more powerful and reliable performance of LEDS, an advanced thermal solution for LEDS is needed, Professional thermal design is key to realize the advantages of LED Lighting. The thermal diffusion technologies (such as using heat pipes, vapor chambers, active cooling fan) can provide excellent thermal management solutions for higher power LED Lighting. Please contact us to discuss your specific LED thermal management application with Yumin cooling teams.

Contact Information: samer@ymcooling.com

URL: Http://www.ymcooling.com