how to use different LED heat sinks to dissipate LED’s heat quickly?

how to use different LED heat sinks to dissipate LED’s heat quickly?

how to use different LED heat sinks to dissipate LED’s heat quickly?

we will analysis depending on heat sink manufacturing Process

l LED heat sink types (LED heat sink manufacturing Process)

heat Dissipation Features:

1. producing complex shapes with high precision and smoothness.

2. require polishing treatment.

3. The mold cost is relatively high, and heat dissipation is poorer than other processes.

4. high production efficiency.

5. low cost for high volume production

Which is often used for lighting fixtures that require large batch production, complex structures, and curved surface aesthetics. (street lights, industry lights)

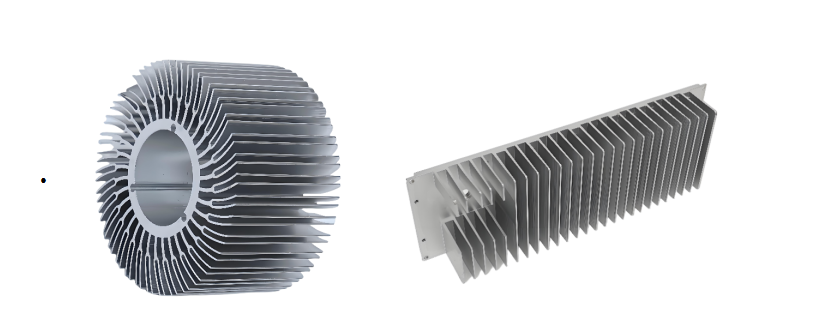

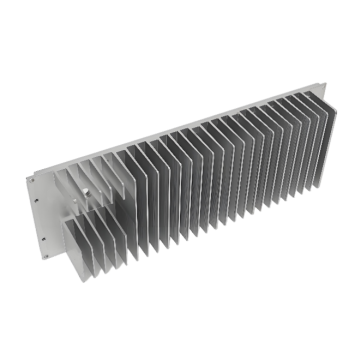

LED extruded aluminum heat sink

heat Dissipation Features:

→relatively low mold cost.

→customized in various shapes and size.

→Higher machining efficiency

→forming is relatively simple.

→thinner Fin, higher thermal conductively.

lighting fixtures that require high heat dissipation performance and relatively simple structure, (downlights, spotlights, stage lights)

·

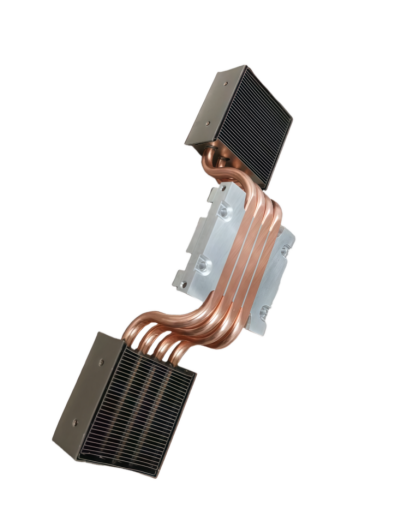

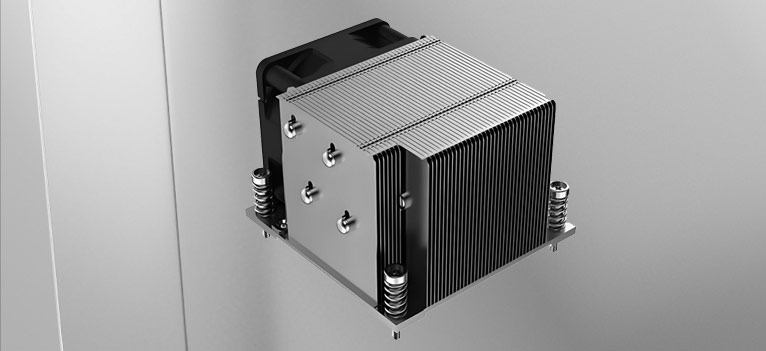

Cold forging Heatsink

high thermal conductivity,

high precision,

and low cost for high volume production

smooth surface finish and good dimensional stability

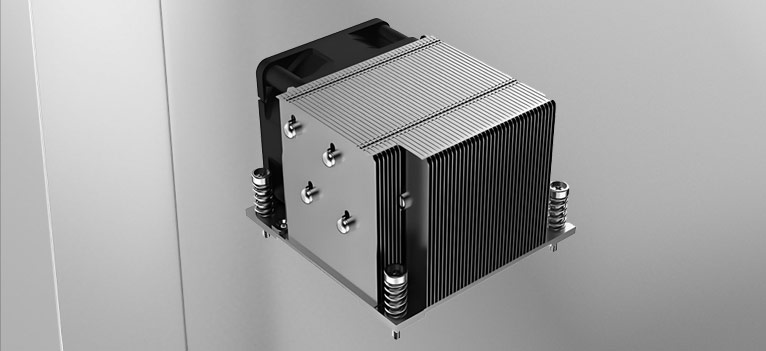

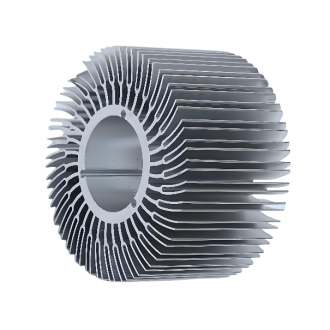

Stacked Heat sink